Cleanroom CSR Approach

Our CSR approach in cleanroom

According to Ellen MacArthur Foundation, circular economy is crucial for creating a sustainable future by preserving resources, reducing waste and environmental impact, while fostering resilience.

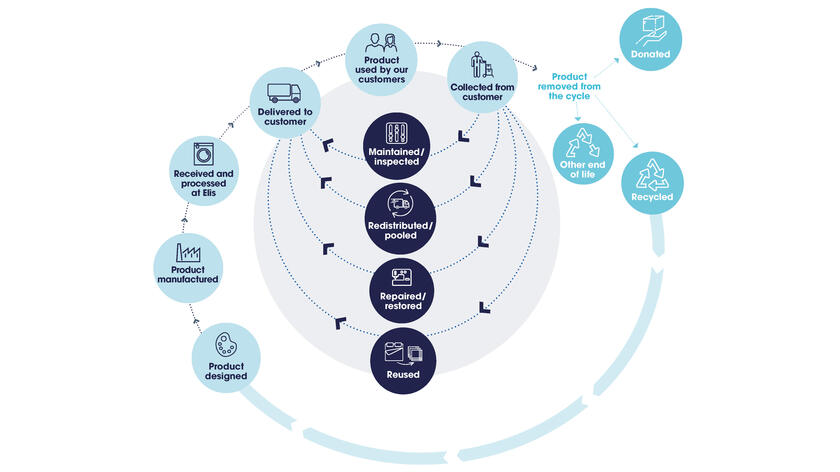

Our business model is based on a circular product as service model and emphasises services over products and rentals over purchases. The service model works in “loops” ensuring our reusable cleanroom garments and accessories stay in circulation for as long as possible. This is enabled by maintaining, pooling, repairing and reusing garments along the way. Finally, end-of-life cleanroom textiles are given a new life by reuse or recycling.

Cleanroom production is, however, very strictly regulated in terms of contamination control. Our circular service model is, therefore, supplemented by contamination control measures such as sterilization, visual inspection, and in-depth quality assurance.

Our journey towards lower resource consumption

Aligned with our excellence and circular DNA, we place a significant focus on reducing resource usage (water, energy, fuel, material…) and diminishing our CO2 emissions.

Below you will find a visual summary of our progress in relation to our CSR commitment:

-

-11%

overall CO2 reduction for Scope 1 and 2

-

-19%

energy CO2 reduction (Scope 1 & 2 electricity and natural gas)

-

-15%

fuel reduction in litres (Scope 1 diesel and gasoline)

-

-20%

water reduction in litres (fresh water and waste water)

-

-41%

waste reduction in kg (commercial and hazardous waste including textile waste)

Which environmental initiatives led to this progress? The answer lies in the video below:

Keeping products in use and working on their end-of-life treatment

We believe in circular economy and where waste becomes a resource.

We place focus on keeping your cleanroom garments in use for as long as possible by maintenance, repair, reuse, and maximum lifetime validation.

When we cannot keep products in use any longer to ensure contamination control, we work constantly to find the best end of life for our products. We build partnerships and innovate along the textile value chain to identify the best ways to valorise our products at their end of life, targeting to reuse or recycle them. We work on projects to “close the loop” and have textile made from discarded textile. Today, our end-of-life products are mostly reused or recycled: into insulating / acoustic materials, furniture, and new textile filling materials.

To achieve that we are engaged in ambitious recycling program together with our partners. For example, in Europe:

- All discarded cleanroom textiles are collected from our sites in a streamlined way.

- Afterwards they are sorted and sent further to recycling facilities.

- We cooperate with experienced textile recycling partners in the market, investigating the latest technologies and ensuring cost-efficient and more responsible handling of end-of-life textiles.

Our international textile R&D collaboration focuses on producing high quality cleanroom fabrics with recycled fibre-to-fibre content.

Subscribe to our newsletter

Message us

Want to know more? Contact us.

Contact Us.

Existing customer

New customer